A highly precise,

fully automated inspection device

which detects sealing defects

in retort pouches and other pouch types.

A highly precise,

fully automated inspection device

which detects sealing defects

in retort pouches and other pouch types.

Manual inspection means many defects are not picked up, so checks are not accurate enough.

Staff shortages make it difficult to manage increased demand

Time consuming inspection leads to a long lead time

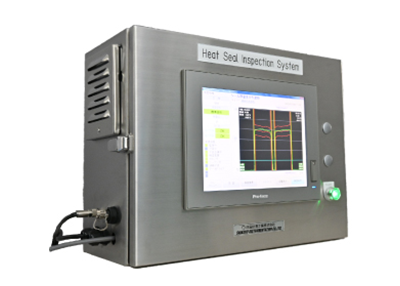

Our Heat Seal Inspection System automatically and accurately detects various problems such as in-seal defects and incomplete sealing, increasing productivity and product quality. Defective items will not slip through the net, which in turn will boost your company's brand image and reliability.

Our Heat Seal Inspection System uses an infrared temperature sensor which detects defects in retort pouches and other pouch types. A highly precise inspection device, it detects in-seal defects, incomplete sealing, or weak sealing, which cannot be detected by the naked eye. It allows weak sealing and packaging machine defaults to be detected early.

Able to inspect up to 125 bags per minute and operate 24 hours a day, 365 days a year, without stopping your production line. It can be attached to an existing rotary style packing and filing machine and takes up minimal space.

Can be used to check when, where, who and how a batch was produced, a highly important feature in recent years in terms of food safety. Able to store two years' worth of inspection data, it can also be used for traceability.

where some of the contents of the pouch has gotten stuck in the sealing

overlapping parts of sealing which lead to wrinkles in the sealing

uneven or distorted sealing (slanted sealing)

two pouches sealed together

not fully sealed, or weak sealing

not suitable for use with pouch vacuum packaging machine

compatible with some types

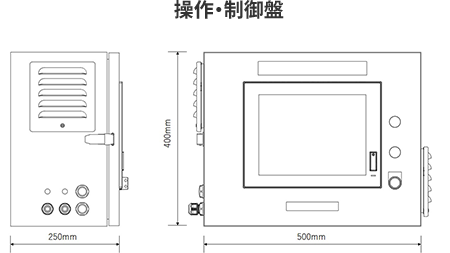

| Items which can be inspected | Retort pouch filling machines (aluminium or resin types) |

|---|---|

| Inspection quantity | Max 125 bags per minute (using a double-barreled filling and packing machine) |

| Inspection system | Non-contact temperature measurement system |

| Functions | Touch panel, learning function, able to store data for up to 999 types of pouch |

| Inspection history | Up to 20 million screenshots (depending on the inspection type) |

| Power | AC220V or 230V, capacity 300VA |

| Types of products which can be inspected | Curry, pasta sauces, soup |

C fast startup disk (read only) which uses SSD to save data. More reliable than HDD, which is prone to unexpected malfunctions causing your system to crash and production line to stop.

The infrared sensor can be connected to up to 2 units at once. It can be used for a variety of different inspection types in one place, or installed in two places, after the first sealing and after the second sealing.

We can recommend the most suitable type of sensor based on the packing machine type, pouch material, and the contents of the pouch which is to be inspected.

"We were reluctant to use automatic inspection devices until now, but with manual inspection human errors are unavoidable, and as a result we received several complaints. We first came across the Heat Seal Inspection Device at a trade fair, and got in touch with Shikoku Instrumentation straightaway".

"Although we weren't in a position to purchase the Heat Seal Inspection Device straightaway due to other machinery being higher on the priority list, looking at its track record we realise just how important it is to avoid customer complaints and have decided to start a trial period".

"We haven't received a single complaint since we started using the Heat Seal Inspection Device, and we no longer need manual inspection staff. We've been using the device since 2014, and its reliability is unbeatable! We'll definitely buy this device again".

No consumables required. We recommend an annual inspection to ensure continued performance.

We usually inspect the top seal of a 3-way sealed pouch. Please contact us using the contact form if you have specific queries about other types of pouches that can be inspected.

You are welcome to send us a sample of the pouch you use, together with its contents, and we will inform you whether or not it can be used with our Heat Seal Inspection Device. Please contact us using the contact form.

Our device is mainly used with single and twin (duplex) rotary type packing and filling machines and placed after the first sealing. Please inform us of the packing machine manufacturer and machine type, and we will let you know whether or not it is compatible with our device.

For details on pricing, please contact us using the contact form.

Shikoku Instrumentation Co Ltd, a subsidiary of Shikoku Electric Power Co Inc, was established in 1951. We begun by manufacturing and repairing watt-hour meters. Since then, we have been using our electronics expertise in the field of measurement and control, and expanded to large-scale core system development for companies.

Invented by our highly skilled and creative engineers, the Heat Seal Inspection System accurately and quickly detects defects that are invisible to the naked eye. The device has been sold to food manufacturing companies all across Japan and is one of our bestselling products to date.

Our main objectives are customer satisfaction, worker happiness and motivation, and the development and safety of the local community and society. We continue to increase our expertise to become a future-facing company.